One of the main themes for the UK’s AMP7 has been smart networks, with water companies investing significantly in additional sensors for their distribution networks. However, many water companies are still only achieving partial coverage (around 20-30%) of their networks despite heavy investment in a variety of approaches, including pressure, acoustics, temperature and flow.

This investment has enabled sensor suppliers to develop the technology behind the sensors, leading to improvements in battery life, accuracy, and communication, as well as lower capital and maintenance cost for each device. However, there is still a long way to go before we reach a tipping point, whereby water companies can justify the roll out of sensors across an entire network against the cost of the investment. There is an ever-increasing challenge to understand the benefits from these investments and build a business case to justify the roll out of more sensors.

Until we reach this tipping point, we need to ensure that the right sensors are deployed where they can deliver the greatest benefit to the water company. We believe this can be best achieved by a combined sensor approach, using a variety of sensors within different environments. This blog will explore some of the solutions on offer and discuss how they can be combined to give the greatest benefit.

Where should we deploy sensors?

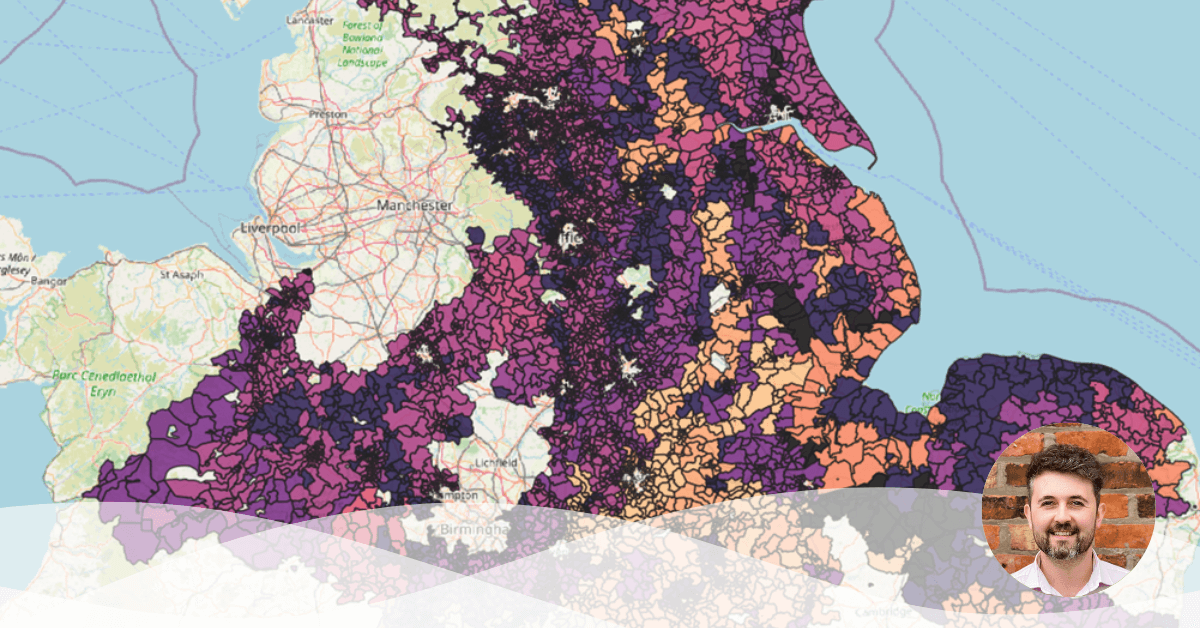

If we have a limited number of sensors to deploy, then it makes sense to ensure we get the best return on investment. The first consideration is to make sure the area has good signal coverage for our chosen communication method (typically NBIOT in the UK). Areas with poor signal coverage may be better suited to a solution that requires fewer sensors, so each sensor’s position can be carefully selected and the communication can be improved locally (e.g. using dedicated chambers or integrated chamber lids).

Secondly, we need to consider the benefit that the sensor will be delivering. For example, deploying sensors in an area with a very low burst frequency is unlikely to deliver as much leakage benefit as an area with a higher burst frequency.

We can also look to take advantage of complimentary systems. For example, a smart meter roll out may create the opportunity to install dedicated chambers for pressure or hydrophone acoustic sensors, as well as a dedicated LPWAN communication network to attach these devices to.

Which sensor should we deploy?

The selected sensor should specifically target the problems we are trying to solve, which will vary across a network.

Accelerometer based acoustic loggers provide a targeted solution to tackling burst leakage. They are simple to deploy and provide a small area of localisation (often correlating down to a few meters). This benefits those areas with a high burst frequency and ensures leakage teams can respond quickly and accurately.

Using pressure sensors for leakage detection doesn’t typically provide the same localisation accuracy as acoustic loggers, but often uses fewer sensors whilst delivering additional benefits for network management. These benefits include, live analysis using digital twins/hydraulic modelling, longer term pressure optimisation (including transient analysis) and regulatory reporting for interruptions to supply. Using the right analysis, pressure sensors can also deliver insight into erratic customer demand, identify network anomalies and detect open DMA boundary valves.

Improved flow monitoring on networks helps us understand where water is going, separating leakage from demand, and customer side losses from distribution network losses. Flow monitoring includes the sectorisation of networks into DMAs and sub-DMA waste metered areas to allow calculation and localisation of leakage. Customer smart metering can be used to identify customer side losses, understand demand, and identify opportunities for water efficiency campaigns.

Hydrophone based acoustic sensors have been widely used within some UK water companies to deliver leakage benefit but require a dedicated installation for long-term deployment which can be a barrier to implementation. The benefits are similar to those from accelerometer based acoustic loggers, but with fewer sensors, correlation for burst events can be less accurate.

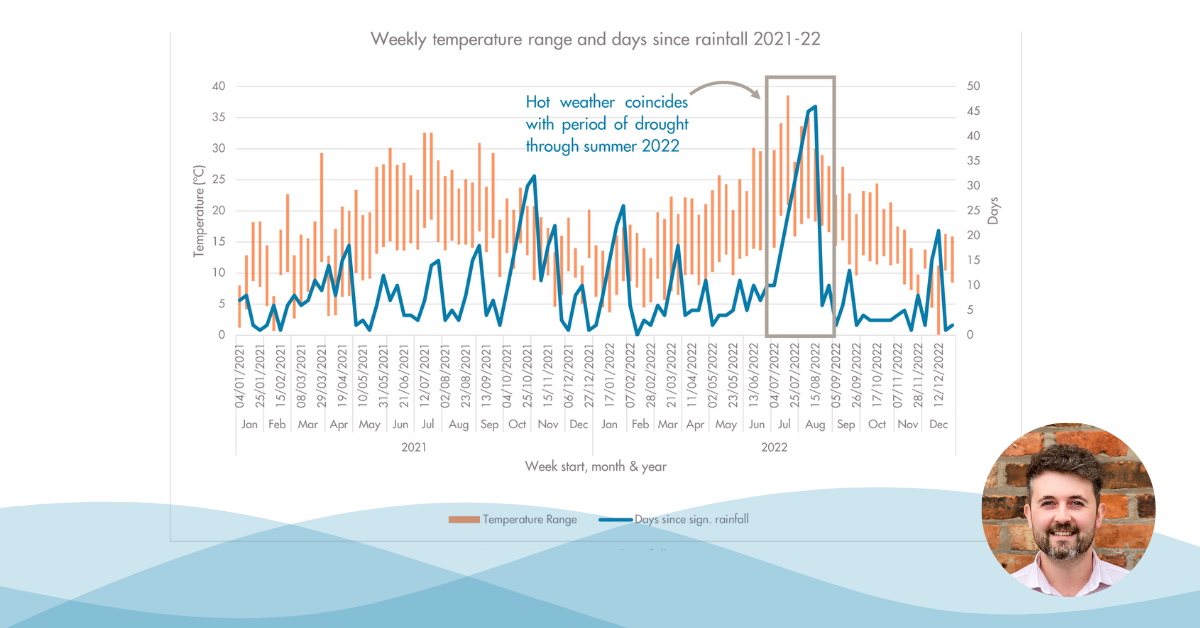

Using temperature sensors is another solution for leak localisation, but their use is still very much in the trial phase, and they have not yet been deployed as a widespread solution by UK water companies.

A combined sensor approach

By combining different sensors, we can maximise the benefits of smart networks. We are currently recommending the following approach to our clients, to optimise their existing sensor network and build business cases for new sensor deployments.

Step 1: Understanding the network

The first step in establishing smart networks should focus on flow and pressure sensing, which can deliver benefit to multiple stakeholders. DMAs should have inlet meters monitored for flow, and then by adding a pressure tapping at the meter a dual channel logger can be installed to monitor pressure for minimal additional cost. Additional pressure points should be added based on the following priority:

Pressure management valves should be monitored downstream, to ensure they are fully optimised and network controllers can identify any failure risks.

Critical points inside each DMA are typically identified as the first place on the network to lose pressure during a peak demand scenario. This data can be used to identify pressure reduction opportunity and manage existing schemes.

Low points in the network allow visibility of the extent of the problem during a supply incident, when pressure data may have been lost at critical monitoring points.

Combined with logging at inlet points, this should result in 3-4 pressure loggers per DMA (assuming a typical DMA size of 1500 properties). This data should allow companies to achieve a high level of network understanding, identify opportunities for network improvement, and support incident management. In addition, most modern loggers have the option to use secondary channels to capture transients, which would also deliver significant insight into network risks.

Step 2: Targeted solutions

Once these flow and pressure solutions have been implemented and networks are understood, additional sensors can be deployed to target specific challenges:

Supply-demand challenges: Where customer smart metering can be justified to the regulator (e.g. due to a wider supply and demand imbalance), establishing this in areas should be a priority. This will deliver significant benefits by separating customer side losses from distribution network losses and promoting water efficiency to customers.

Burst and leakage management: Permanent acoustic logging delivers fantastic benefits for leak localisation, but it is important that this is implemented at a sub-DMA level, identifying parts of the network which have both a high risk of bursting and good communication to ensure that sensors work effectively and generate a return on investment. This will reduce overall leakage levels by ensuring teams react to new bursts quickly and accurately.

Supply interruptions and C-MeX: Pressure logging provides immediate awareness of network issues and should be implemented in areas where a network issue will cause a significant disruption to customers. Increasing pressure logging to 6-8 sensors per DMA will allow the implementation of real time analysis tools (e.g. Dynamo) and digital twin solutions, which can notify network controllers of issues in near real time and support localisation of events on the network. An increase to 9-10 loggers per DMA will increase confidence in outputs and deliver more accurate localisations.

Summary

By establishing a high level of network understanding first, operators can ensure that additional sensors are deployed in the places where they will deliver the greatest benefit. We recommend that a skeleton of flow metering and pressure sensors (3-4 per DMA) is established with additional flow, pressure, and acoustic sensors then added to areas where they can be justified against a specific risk and benefit.