Permanent acoustic logging has matured as a leakage detection technology over the last decade and, as such, has been rolled out by a number of water companies during the last AMP cycle. While different hardware manufacturers have taken markedly different approaches to the data being collected, the basics of the technology itself are the same. The essential property of all acoustic loggers is that they ‘listen’ to the sounds being produced on a network with the aim of providing useful localisations of possible leaks. They are generally designed to make recordings at set intervals, most often at night when network activity is lowest and pressure is highest, with analysis of the sounds ‘heard’ providing insight into what might be happening on a network. This blog will discuss some notable aspects of the available hardware as well as the methods of data collection and processing currently seen in the market and what might be expected in the future.

Hardware

In terms of what hardware is available, an early distinction to draw is the difference between hydrophones and accelerometer-type devices. Both have their pros and cons and the optimal use of each very much depends on the characteristics of the network they are being used to cover. The key difference between the two is that, where accelerometer type devices can be attached magnetically to a valve or fitting, hydrophones must be in contact with the water inside the pipe. The result of this is that hydrophones may be slightly better at picking up the sounds being carried inside a pipe and that more accelerometer units are necessary to cover the same area of network. However, this is to be balanced against the relative ease of attaching an accelerometer.

The first observation then, among the deciding factors for potential buyers of the technology, is that the number of fittings available on a network matters. In areas where fittings are not abundant, hydrophones might present an advantage in terms of network coverage, where, in other areas, the convenience of an easily attached and non-intrusive device might take precedence.

In either case, the collected data is transmitted and collated in different ways too. In recent years, there has been a steady move away from using ‘repeaters’ as a method of data transmission as technology advances. Repeaters have been recognised as a potential point of failure in the chain of data transmission and so manufacturers are increasingly opting for more reliable methods, utilising technologies including 3g/4g, LTE-M and NBIoT. Most notably in areas that have been prone to comms difficulties in the past, these newer technologies have the potential to significantly reduce the run-time of leaks.

Accelerometers have been the most commonly used devices by the clients with whom SME Water has been working of late and so this blog will focus primarily on these from here on out.

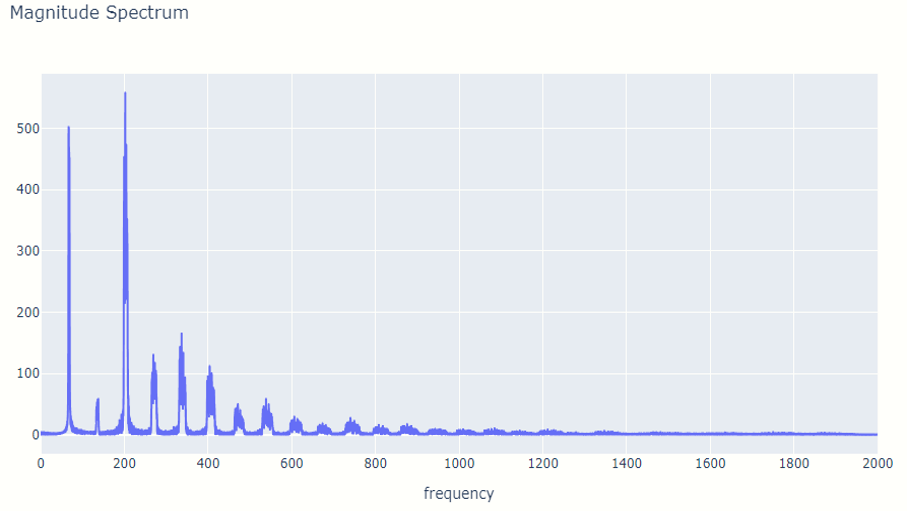

The newest generation of loggers are compact, integrated devices that are very capable of reducing both awareness time and time-to-find for those carrying out leakage detection activities. Traditionally, these loggers offer a battery life in the region of three to five years, depending on how they are configured and how much data is required of them. As battery life continues to improve thanks to a range of technological advances, we are starting to see notably longer lifespans being achieved. Significantly impacted by pipe materials and potential ambient noise sources, it is important for those intending to use permanent acoustic loggers to consider their deployment strategy carefully. For example, plastic pipes do not transmit sound waves as effectively as metallic pipes and so loggers on plastic networks must be deployed closer together to achieve the same level of network coverage. Similarly, nearby electrical installations such as streetlights will produce distinctive interference in acoustic data at 50Hz intervals, another factor worth considering when deploying loggers. An example of electrical interference is presented below: