Every water network from urban distribution pipelines to groundwater wells experience changes in pressure. Water companies often focus on flow rates, demand forecasting, and system efficiency but one of the most dynamic, least understood phenomena in their networks is the pressure transient.

As part of a Knowledge Transfer Partnership (KTP), we are developing a cutting-edge platform to better understand and manage pressure transients in water networks. Being a KTP helps to bridge the gap between academia and industry, enabling innovation to move from research into real-world application. Through this partnership, we’re working to give water companies the tools to capture, analyse, and act upon transient events.

For further information on KTPs and how they drive innovation, please see this link. Knowledge Transfer Partnership guidance – UKRI

Pressure transients are short-lived events that can tell powerful stories about what is really happening inside a water network. Yet, for decades, they have been largely overlooked. Why? Because they are brief, unpredictable, and often invisible until something goes wrong.

This blog explores what these transients are, why they matter, and how emerging techniques like transient logging are revealing their hidden stories.

A pressure transient is a rapid change in pressure within a pressurised pipeline system, typically resulting from a sudden change in flow conditions. Pressure transients are often referred to as “water hammer” because of the characteristic hammer-like knocking sound or vibration they can produce in pipes. This phenomenon occurs due to the momentum of the moving water and the fact that water is nearly incompressible. When water is flowing steadily and a valve closes suddenly or a pump stops abruptly, the moving mass of water still carries significant momentum. Because water cannot easily be compressed, the sudden stop forces the energy of this moving mass to be transmitted almost instantaneously as a pressure wave.

When a pump stops suddenly, a valve closes too quickly, or there is a rapid change in demand, the momentum of the moving water is abruptly altered. This change in momentum creates a pressure wave that propagates along the pipeline. This wave travels at a speed close to the speed of sound in water (typically 1,000–1,400 m/s), depending on pipe material, wall thickness, fluid temperature, and elasticity of both the pipe wall and the water. If the pressure wave is strong enough, it behaves like a shock wave, propagating rapidly and reflecting at boundaries (valves, junctions, pumps, or reservoirs). Each reflection can create oscillations in pressure sometimes causing audible banging, pipe vibrations, or even bursts.

The intensity (or pressure change, ΔP) can be estimated using the Joukowsky equation:

Δp = ρaΔv

Where:

- Δp = change in pressure (Pa)

- ρ = density of water (kg/m³)

- Δv = change in fluid velocity (m/s)

This explains why transients are not just theoretical curiosities: they propagate rapidly, affect large sections of the network, and can create both immediate and long-term risks if left unchecked.

Most traditional pressure monitoring systems record data at 15-minute intervals. This is fine for tracking daily fluctuations, but completely inadequate for detecting pressure transients, which can happen and disappear in milliseconds.

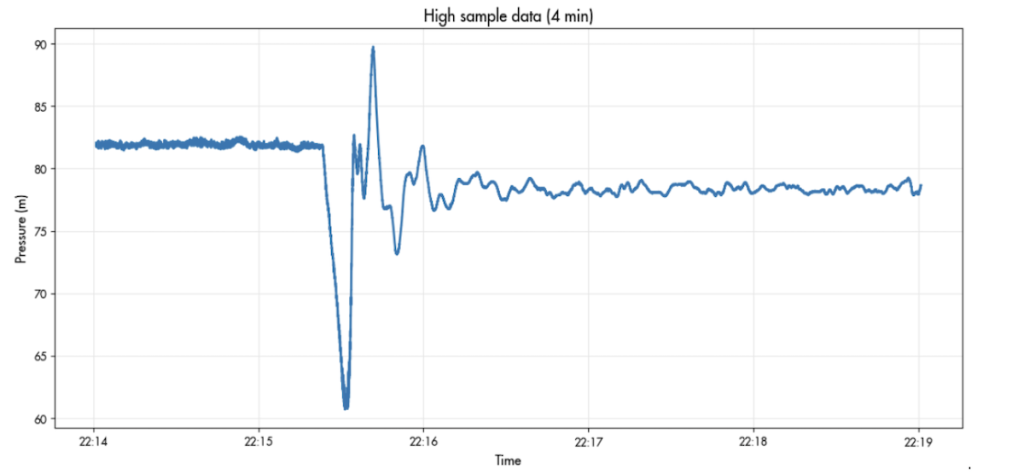

The figure below shows pressure vs time graph for high sample pressure data from a transient logger:

Figure 1: Pressure vs. Time graph

The sharp dip and spike represent a transient event, lasting milliseconds to seconds. Without dedicated logging, this would be lost between standard sampling intervals.

This brief “blip” may look harmless, but repeated hundreds of times a day, it can stress pipes, loosen joints, and accelerate fatigue on the pipe network or fittings or both. In some cases, that small dip might signal something more serious like a minor leak forming or a valve malfunction.

Transient loggers are specialised pressure sensors designed to sample at high frequencies (often 100–1,000 samples per second or more). Instead of providing a slow trend line, they capture the fine details of pressure fluctuations as they happen.

What does transient logging enable?

- High-resolution event capture: Even very short events are recorded in full detail.

- Event triggering: Loggers can be set to start recording when a sudden pressure change exceeds a threshold.

- Network-wide correlation: When deployed across a network, multiple loggers can triangulate the source of a transient.

- Data for root cause analysis: Helps determine whether a surge came from a pump, a valve, or an external disturbance.

Transient logging transforms transients into analysable, trackable data points.

Many water companies have adopted a lift-and-shift strategy of transient logging for a cost-effective coverage. Instead of buying hundreds of loggers upfront, they deploy loggers at high-risk areas for a specific period, capture and analyse the transient data during that period, before moving the loggers to a new area of the network based on findings or operational priorities. This rolling approach maximises the value of each logger, turning a small fleet of devices into a network-wide investigation tool.

Our understanding of everyday transients is still limited. Most water companies generally monitor pressure at low sampling rates, which completely misses the high-frequency nature of transient events. We are yet to understand a lot more about transients. How often transients occur across typical water networks? Are all transients bad for the network? What cumulative damage they cause over years of operation? How best to categorise, classify, and predict them? This knowledge gap must be filled to better understand a major source of stress affecting water company assets.

Some of the important reasons why pressure transients are worth investigating are:

- Early Leak Detection

Leaks and bursts often create distinct transient signatures. When a pipe suddenly bursts or a significant leak develops, it represents a rapid change in flow conditions. By analysing the timing, frequency, and shape of these pressure waves, it is often possible to not only detect that a burst or leak has occurred but also estimate its location and severity.

- Preventing Damage

Repeated surges can lead to fatigue in pipes, valves, and joints. Knowing where these occur allows for targeted operational changes (e.g., adjusting pump turn on/off speed or valve closure rates).

- Improving Operational Efficiency

Sometimes, pressure transients reveal inefficiencies in how the system is run: pumps stopping too abruptly, valves opening without coordination, or sections of the network prone to sudden demand shifts.

- Extending Asset Life

Proactive transient monitoring helps water companies protect their most expensive assets by reducing wear and tear.

- Building a Smarter Network

With modern sensors and analytics, transients can become part of a water company’s cloud-based analytics feeding into predictive maintenance models and smarter planning.

Pressure transients have always been there. What’s new is our ability to see them, understand them, and act on them accordingly and use that knowledge to make better decisions. Investigating them offers a chance to reduce costs, prevent failures, and make smarter decisions for the future of water infrastructure.

So, by combining transient logging with smart analytics, we can build a platform for pressure transient analysis and diagnostics which turns high-frequency transient data into meaningful insights. It helps water companies make informed, proactive decisions whether to prevent bursts, extend asset life, or optimise pump schedules, protecting billions in water infrastructure.