Introduction

We found an interesting occurrence recently while conducting some pressure analysis for a client. The project involved pressure sensors being installed in dual boundary boxes and comparisons being drawn with the pressures being recorded at the nearest hydrant on the network. We aimed to determine how effectively logging at a boundary box could replicate monitoring on the network and investigated throughout December 2022, which, you may remember, had a particularly fierce cold snap in the run up to the festive season. As it turned out, this cold snap had a significant impact on our pressure sensors’ transducers, but not uniformly so.

This blog lives at the intersection of the impact of cold weather on electronics and the dos and don’ts of pressure monitoring.

Background

Before we dive into that though, let’s run through what a transducer actually is. Put simply, transduction is the process of converting one form of energy to another, and a transducer … well, you guessed it! (ed: yes, it converts energy from one form to another). An electrical transducer is capable of converting physical quantities into a proportional electrical quantity, turning such things as pressure, level, temperature etc into a useable electrical signal. To be more specific, any device that is able to convert one form of energy to another is called a transducer, for example a speaker turns an electrical signal into sound waves, but an electrical transducer will convert a physical quantity to an electrical signal.

In our case, the transducers were converting the physical quantity of pressure into an electrical signal. The signal is produced as a function of the pressure applied to the sensor, meaning we can infer pressure by the voltage reading, allowing us to monitor changes in pressure on the water network. SO, that’s how pressure logging works.

The investigation

While carrying out our investigation of pressure at hydrant and boundary box, we realised that a high proportion of sensors attached to the former had acted differently to those placed in the latter. The cold snap, which lasted the best part of two weeks in the middle of the month, saw a third of sensors that had been installed on hydrants begin sending bad data, where none of those attached to dual boundary boxes had suffered the same fate.

This was immediately of interest to us. Had we just discovered a fringe benefit to boundary box logging?

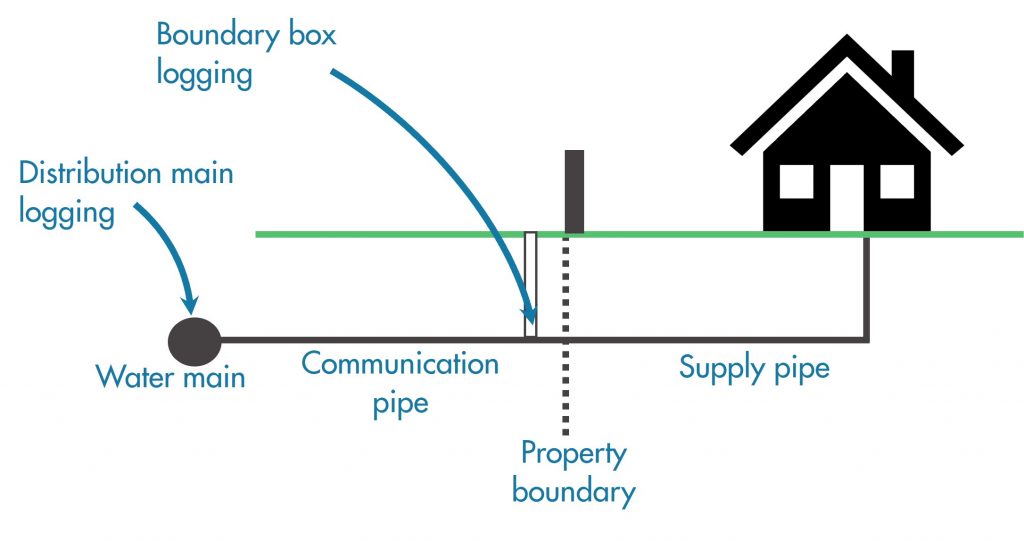

We knew that boundary boxes are often installed with a polystyrene plug which might act as a thermal insulator for the contents of the box, which is buried underground – as shown below. We were keen to find out if this plug in the top of boundary boxes might help protect the sensors inside to a greater degree than we had previously thought likely.

We contacted the supplier of the pressure sensors to gain their input on what might be happening.

While the plug may well provide some protection from the cold, the manufacturer of the sensor equipment was able to offer a different perspective. In the type of sensor we used, a hose connects the unit to the water network which allows the pressure to be measured internally by the sensor. We were told that a likely cause of the problem for those loggers in hydrants that began sending bad data was that they had been connected to the network using an uninsulated hose that was touching the metal lid of the hydrant. This would have the result that the water in the hose would freeze and cause bad results in the excessively cold temperatures just before Christmas.

While our dataset was not large we can say that the sensors in the boundary boxes we were using were not affected by the cold weather to the same degree as those located in hydrants, presenting a possible avenue for further investigation.

Lessons learnt

There are two recommended solutions to the problem posed by chilly transducers:

- The first option would be to use an external transducer. External transducers connect to the main via a wired cable and so do not run the risk of the connection freezing in cold weather.

- A second option would be to thermally insulate the hose that connects sensor to network to prevent the water inside from freezing.

So, network monitors and leakage hunters of all descriptions, there you have it. Be ready for the next cold snap! Harbour your hoses! Tend your transducers! Protect your pressure data!